Paper Industry

Application Introduction

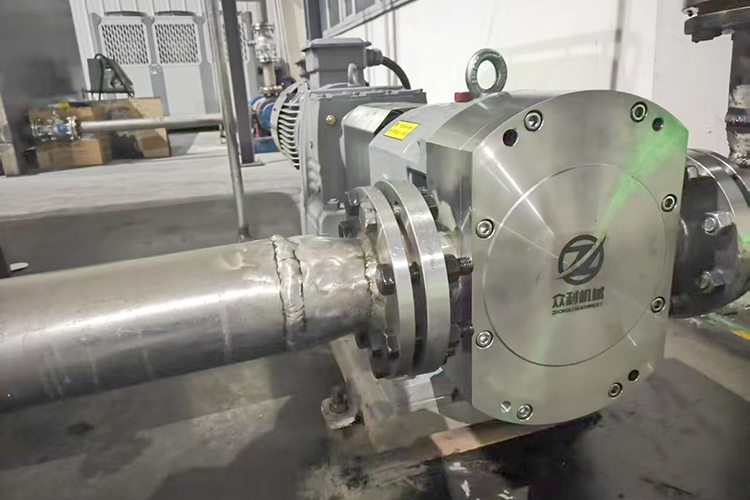

Pumps for paper industry

The paper industry is an important industry closely related to our daily life, which provides us with a wide range of paper products to meet the needs of people in writing, printing, packaging and so on. Paper’s main raw material is wood fiber, in addition to the use of waste paper, non-wood fiber (such as straw, wheat straw, bamboo fiber, etc.) as raw materials. With the continuous progress of science and technology and environmental awareness, the production process requires the continuous introduction of advanced automation equipment and information technology to improve production efficiency and product quality. Pumps play a vital role in the papermaking process and are used to convey various liquids and slurries.

Providing solutions for a wide range of conditions

With several challenging applications in the paper industry, our application proprietary technology in specific pump designs is critical to our customers. Zongli ZL series rotor pumps are widely used in: cooking starch, paint and sizing agent, dry strength agent, rosin glue, PAM and other types of chemical materials transfer.

- Paint loading: In the coating process, the paint is conveyed to the coating equipment, the paint conveying needs to be able to precisely control the flow and pressure. Paint contains many kinds of chemicals, Zongli ZL rotor pumps are equipped with special customized seals, which greatly improves the service life of the seals.

- Chemical transportation: In the process of paper production, various chemicals need to be added. The conveying process puts higher requirements on the pump’s self-priming ability, stable metering and material requirements.

- Starch conveying: Cooking starch, sizing up the material conveying process, the pump’s temperature resistance requirements, pulse smoothness put forward higher requirements.

Zhongli rotor pumps can offer you

- Safety relief valve, guaranteeing safety

- Online maintenance, continuous production

- Can be forward and reverse, to meet the different installation needs on site

- Components are common, reducing inventory

- A variety of sealing types, applicable to all kinds of media

Zhongli high pressure plunger diaphragm pumps can offer you

- No shaft seal design, no leakage

- Avoid disassembly leakage of oil, to prevent the diaphragm back end of the air intake

- Fewer wearing parts, quick replacement, low cost

Zhongli Twin-screw pumps featured advantages

- The screw No contact between screw and pump chamber, can run in reverse

- Axial conveying, lower shear rate

- Stable conveying, no pulsation and vibration

How It Works

-

Rotary lobe pumps

-

Emulsification Pumps

-

Twin Screw Pumps

-

High pressure plunger diaphragm pumps