Fine Chemical Industry

Application Introduction

Pumps for Fine Chemical Industry

With the evolution and development of the fine chemical industry, The market size is also expanding.From deeply processed chemicals to high value-added new materials, The variety of fine chemical products is increasingly rich, to meet the needs of different fields, and further promote the prosperity of the market. The fine chemical industry has a wide variety of products and processes, which requires safe, environmentally friendly and stable conveying equipment, as well as easy maintenance and high energy efficiency.

Solutions for various application requirements

- For the fine chemical industry product characteristics, process differences and environmental safety requirements, we give full play to the advantages of application technology to provide you with a variety of working conditions customized conveying pumps, effectively protect the continuity of production and product quality stability. At the same time, we enhance the efficiency of resource and energy utilization to realize the greening, cleaning and recycling of the production process and products.

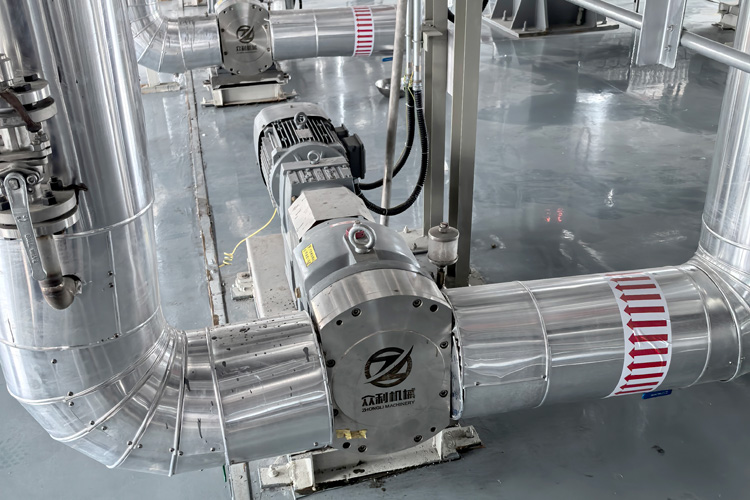

Zhongli rotor pumps can offer you

- Safety relief valve, guaranteeing safety

- Online maintenance, continuous production

- Can be forward and reverse, to meet the different installation needs on site

- Components are common, reducing inventory

- A variety of sealing types, applicable to all kinds of media

Features of Zhongli high pressure plunger diaphragm pumps

- No shaft seal design, no leakage

- Avoiding oil leakage from dismantling and preventing air intake at the back end of the diaphragm

- Fewer consumable parts, quicker replacement, lower cost

ZL Twin-screw pumps features Advantages

- No contact between screw and pump chamber

- can run in reverse

- Axial conveying, lower shear rate

- Stable conveying, no pulsation and vibration

How It Works

-

Rotary lobe pumps

-

Emulsification Pumps

-

Twin Screw Pumps

-

High pressure plunger diaphragm pumps