Chemical Fiber Industry

Application Introduction

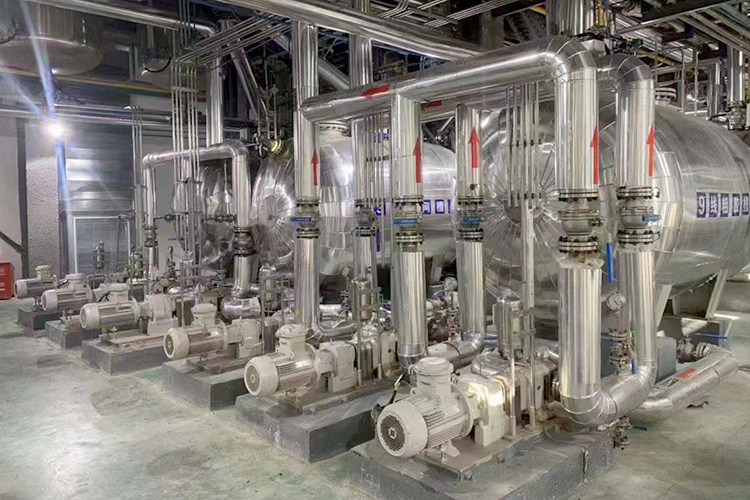

Pumps for the chemical fiber industry

Pumps for chemical fiber industry play an important role in chemical fiber production, and their selection and use directly affect the production efficiency and product quality. With the development of industry 4.0, pumps for chemical fiber industry are developing in the direction of intelligence, and the performance and reliability requirements of pumps will be higher and higher.

Provide solutions for various working conditions

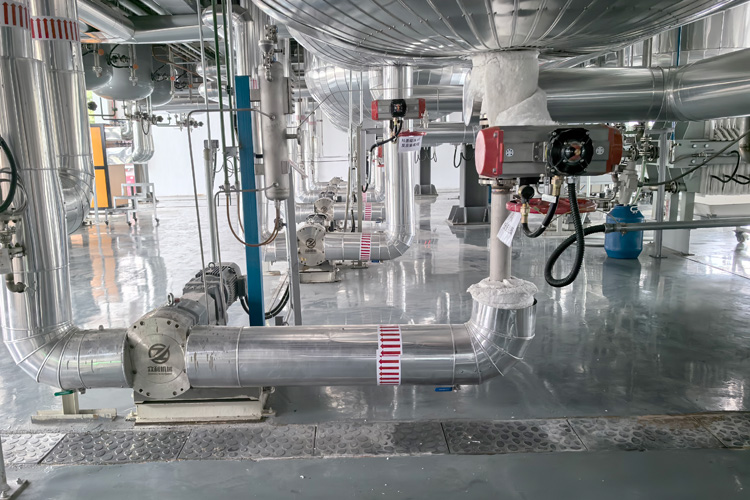

ZL rotor pumps in the chemical fiber industry is widely used in: slurry porridge, viscose slurry, PVA, spandex slurry, Vylon slurry, acrylic slurry, and other materials conveying.

- Slurry porridge conveying: slurry crushed and soaked in liquid alkali to form a similar porridge-like material is called slurry porridge.ZL rotor pump is suitable for impregnation barrel transfer, press feeding and other conditions because of its stable transport, corrosion resistance and other advantages.

- Viscose conveying: viscose conveying is a key link, due to viscose has high viscosity, easy to solidify, corrosive and other characteristics, at the same time viscose impurities will affect the quality of spinning, so the production process will be used in multi-stage filtration technology (such as plate and frame filtration, candle filtration) to ensure that the purity of the viscose, ZL developed the viscose pump with low pulse, stable operation, high corrosion resistance, high efficiency and energy saving, etc. is suitable for the production of all aspects of viscose conveying. ZL rotor pumps are suitable for conveying viscose in all stages of the production process.

Zhongli ZL rotor pumps Can offer you

- Various rotor forms to choose from, to meet the needs of different working conditions

- Online maintenance, continuous production

- Can be forward and reverse, to meet the different installation needs on site

- Components are common, reducing inventory

- A variety of sealing types, applicable to all kinds of media

ZL grinder pump features

- No shaft seal design, no leakage

- Avoid disassembly of the leakage of oil, to prevent the diaphragm back end of the air intake

- Fewer wearing parts, quick replacement, low cost

ZL Twin-screw pumps features Advantages

- No contact between screw and pump chamber

- can run in reverse

- Axial conveying, lower shear rate

- Stable conveying, no pulsation and vibration

How It Works

-

Rotary lobe pumps

-

Emulsification Pumps

-

High pressure plunger diaphragm pumps

-

Twin Screw Pumps