Environmental Industry

Application Introduction

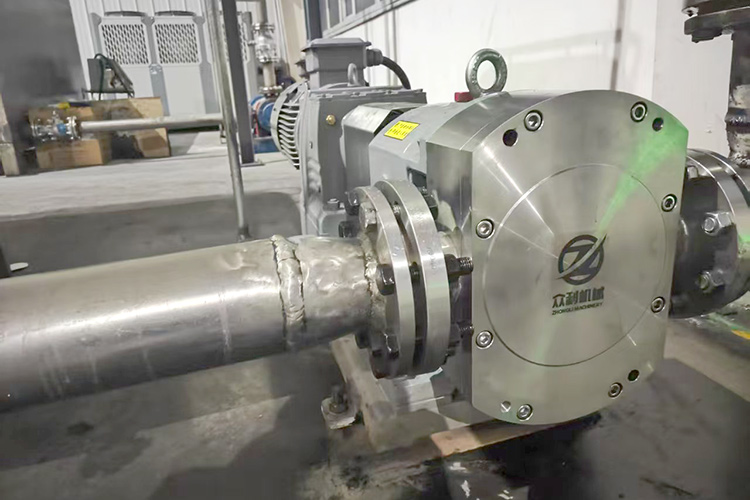

Pumps for the environmental protection industry

Pumps for environmental protection refer to the pump equipment used in water treatment, waste gas treatment, solid waste treatment and other environmental protection projects. The environmental protection industry has high requirements for pumps, especially in terms of corrosion resistance, abrasion resistance, high temperature resistance, no leakage and so on. As the media handled in environmental protection projects are usually characterized by corrosiveness, solid particles or high viscosity, the selection and design of pumps need to take these factors into special consideration.

Solutions for various applications

- Activated sludge reflux: activated sludge method is a common wastewater treatment process, and some activated sludge needs to be refluxed to the front-end reaction tank during the treatment process. the low shear characteristics of ZL rotor pump can avoid destroying the microbial structure of activated sludge, maintain its activity, ensure the effect of wastewater treatment, and accurately control the amount of refluxed sludge to optimize the concentration of microorganisms in the reaction tank.

- Impurity-containing wastewater conveyance: wastewater produced by industrial production often contains a large number of solid impurities, fibers, etc., such as textile printing and dyeing wastewater containing printing and dyeing residues, fiber filaments, food processing plant wastewater with food residues, etc. ZL rotor pumps installed with appropriate filtering devices can effectively set aside the impurities to prevent clogging, and smoothly convey this type of complex industrial wastewater to the treatment equipment.

- High-concentration organic wastewater treatment: chemical and pharmaceutical industries produce high-concentration organic wastewater, which has complex composition and may be corrosive, ZL rotor pump adopts corrosion-resistant materials, such as 316L, 2205, 2507 for pump body and perfluoroelastomer for seals, so that it can withstand the corrosion of wastewater and be stably transported to the anaerobic reactor, aerobic tank, etc. for treatment.

Zhongli rotor pumps can offer you

- Safety relief valve, guaranteeing safety

- Online maintenance, continuous production

- Can be forward and reverse, to meet the different installation needs on site

- Components are common, reducing inventory

- A variety of sealing types, applicable to all kinds of media

Features of Zongli high-pressure plunger diaphragm pump

- No shaft seal design, no leakage

- Avoid disassembly oil leakage, prevent diaphragm back end from air intake

- Fewer wearing parts, quicker replacement, lower cost

ZL Twin-screw pumps features Advantages

- No contact between screw and pump chamber

- can run in reverse

- Axial conveying, lower shear rate

- Stable conveying, no pulsation and vibration

How It Works

-

Rotary lobe pumps

-

Emulsification Pumps

-

High pressure plunger diaphragm pumps

-

Twin Screw Pumps